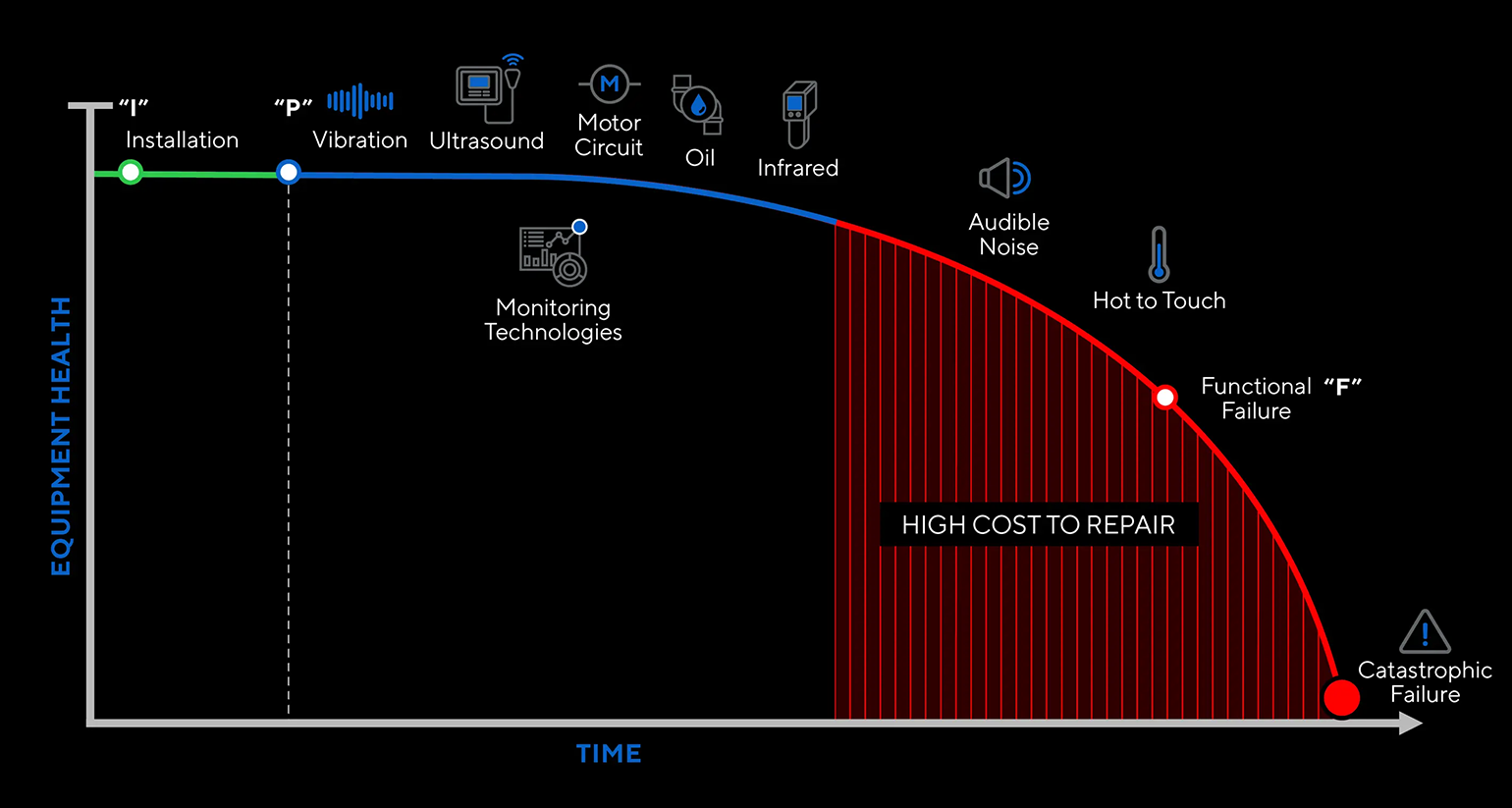

What better way to spend an afternoon than to debate which came first, the chicken or the egg? One thing that cannot be debated, however, is the fact that abnormalities come before failures. This is a fact.

We are conditioned early on to react to failures, the loss of function, why did the lights go out? Why did my car stop working? The abnormalities that lead to these failures often fly below our radar. This ability to change our thinking or refine our attention to look for abnormalities is the first critical step in transforming from a reactive to a proactive organization. Reactive organizations attribute their performance to bad luck, proactive organizations make their own luck.