Keeping Your Oil Analysis Program Up to Date

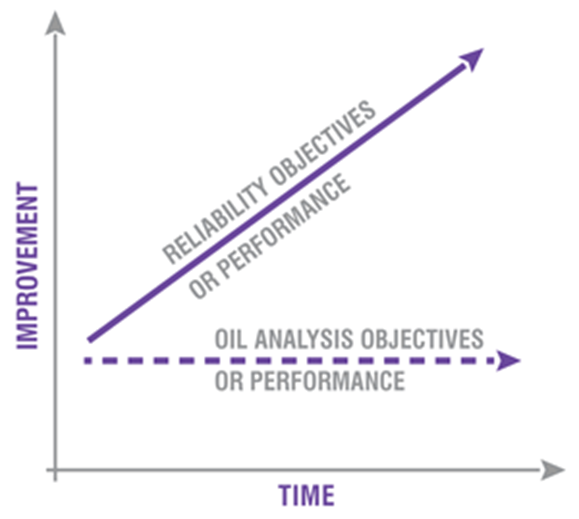

Over time, any oil analysis program can become stagnant if few or no improvements are made. This can cause the program to lose value, as it may not fully support your plant’s improvement initiatives, such as achieving certain reliability objectives. What’s worse is that the program manager may not even be aware of the decline.

In order to determine whether your oil analysis program is up to date, ask yourself the following questions:

- Do you review the program’s objectives at least on an annual basis?

- Have you implemented new reliability objectives for machines in the oil analysis program without updating the program’s objectives or parameters?

- Have you implemented other predictive technologies for machines in the oil analysis program without updating the program’s objectives or parameters?

- Has your program been in use for years without being reviewed?

- Is your plant analyzing historical information to assess the program’s effectiveness?

- Is there at least one person in your facility who has the formal training and experience to design, implement, and manage the oil analysis program?

If you answered “no” to more than one of these questions, it may indicate that your program needs to be updated or reviewed. Fortunately, the solution is not overly complex. A systematic approach, along with a good understanding of oil analysis, will enable you to update your program with relative ease. Below are several tips to help ensure continuous improvement.

Reviewing Program Goals

First, you must review the program’s goals and assess how it is fulfilling the current reliability needs. When the program was implemented, there likely were goals and expectations. Now it may be time to reassess or confirm whether the objectives should change or remain the same.

It’s also possible that the original objectives were not specifically defined. If this is the case, you must take the time to properly define them according to the reliability program.

For instance, the objectives may be predictive (monitor wear debris), proactive (help control contaminants in the oil), or focused on specific initiatives (verify lubricant life and performance).

The objectives should be based on the machine’s typical failure modes and the use of other predictive technologies. Be as specific as possible because this will be the reference information you will use to update the program.

A good question to ask is whether management and the program manager are satisfied with the program’s capabilities and results. If there are concerns about the quality of the program or a perception that it is not fulfilling needs or expectations, these issues should be discussed and considered as part of the review.

Of course, the program manager should have a solid grasp of oil analysis interpretation and program management to be able to coordinate this task effectively. Take a look at How to Interpret Oil Analysis Reports for more detail on this.

Updating the Program

Once the objectives have been reviewed, the next step is to verify that all of the factors involved are fulfilling their purpose within the program. These factors include test slates, sampling frequencies, sample locations, sampling technologies, procedures, and lab services. The necessary adjustments should then be made to each of these elements and supported by appropriate training of field personnel.

Remaining Flexible

An oil analysis program should be flexible and dynamic to provide all the essential information about your lubricant. You may need to update the program policies, so you can implement best practices. Use the questions at the beginning of this blog as a guide. Then determine what would be required to achieve an affirmative answer to all the questions.

Remember, a world-class program may also have temporary or specific objectives from time to time based on reliability needs, such as assessing filter quality, investigating a particular root cause, or conducting additional tests to learn more about a product’s performance.

The benefit of staying updated and operating with more flexibility is that you will develop a stronger oil analysis program that can fully support your reliability strategy, today and tomorrow.

ABOUT ALLIED RELIABILITY

Allied Reliability provides asset management consulting and predictive maintenance solutions across the lifecycle of your production assets to deliver required throughput at lowest operating cost while managing asset risk. We do this by partnering with our clients, applying our proven asset management methodology, and leveraging decades of practitioner experience across more verticals than any other provider. Our asset management solutions include Consulting & Training, Condition-based Maintenance, Industrial Staffing, Electrical Services, and Machine Reliability.

Subscribe to our Blog

Receive the latest insights on reliability, maintenance, and asset management best practices.