The Asset Management Ecosystem through a Digital Lens

HOW ASSET-INTENSIVE INDUSTRIES CAN IMPROVE RELIABILITY WITH DIGITIZATION

Overview

With the vast array of digital capabilities now available, it is important to look at the entire asset management (AM) ecosystem and its current level of maturity to take full advantage of available technology solutions. Conducting an analysis of your organization’s current AM state will help to:

- Employ digital tools that add value now

- Avoid digital investments that do not add value

- Focus on foundational developments to enable continued digitization

- Manage the pace of change with consideration for your people and their capabilities

- Avoid wasteful organizational churn

The asset management ecosystem

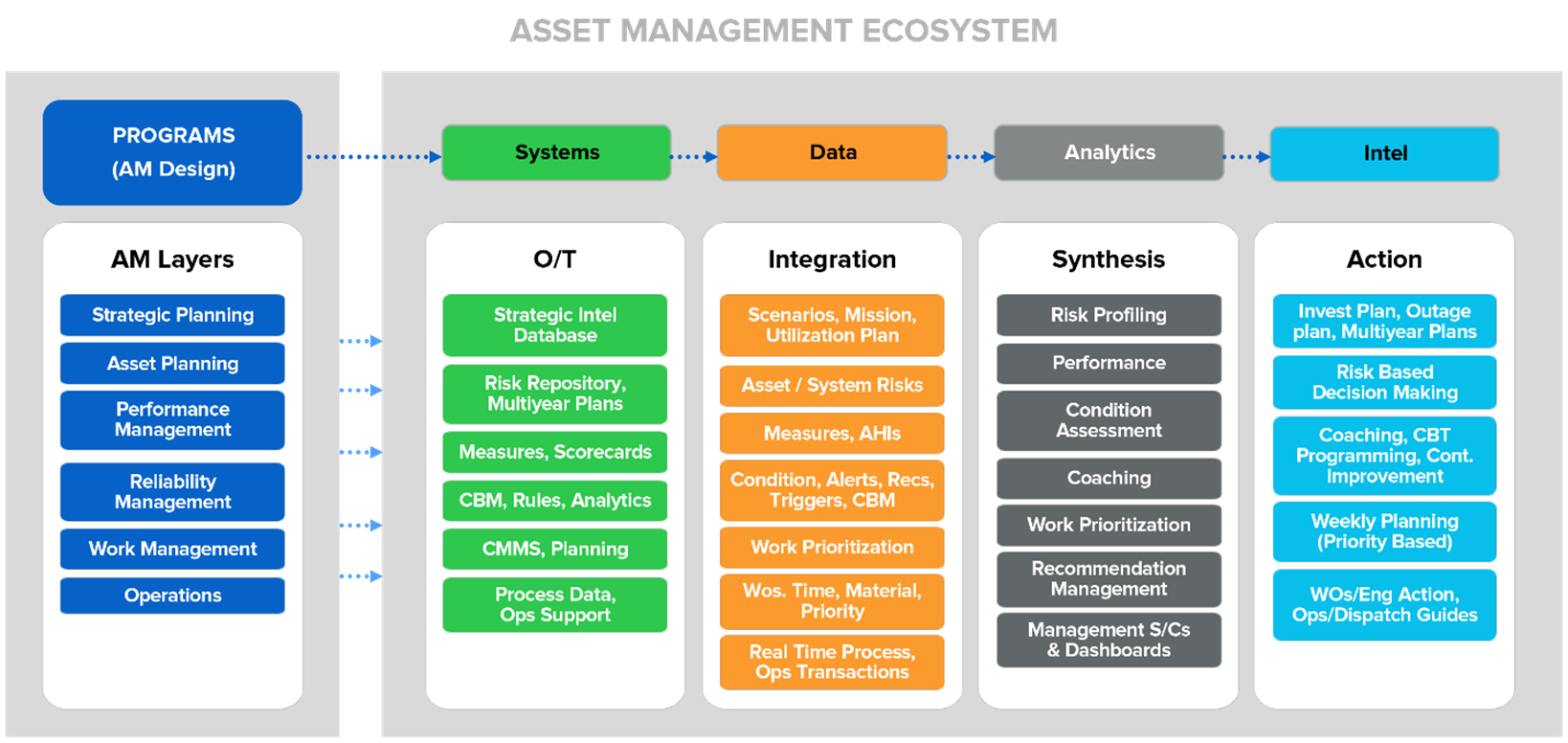

The AM ecosystem is a structured organization of programs, systems, data, analytics, and actionable intel (intelligence). Refer to the diagram below.

The main AM “streams”, (columns), are subdivided into corresponding “layers” of AM-related activities performed in various functional areas. The streams are described as follows:

- Programs —describes the processes, systems, data, analytics, intel, and associated goals and objectives. This identifies how streams integrate, who is responsible, and how they are managed.

- Systems — selected and designed to meet the requirements of the AM program.

- Data — specified and managed to support analytics.

- Analytics — lead to intel which drives short term decision-making (Condition Based Maintenance for example) and longer-term decision making (Risk Based Decision Making) enterprise wide.

The Asset Management Assessment

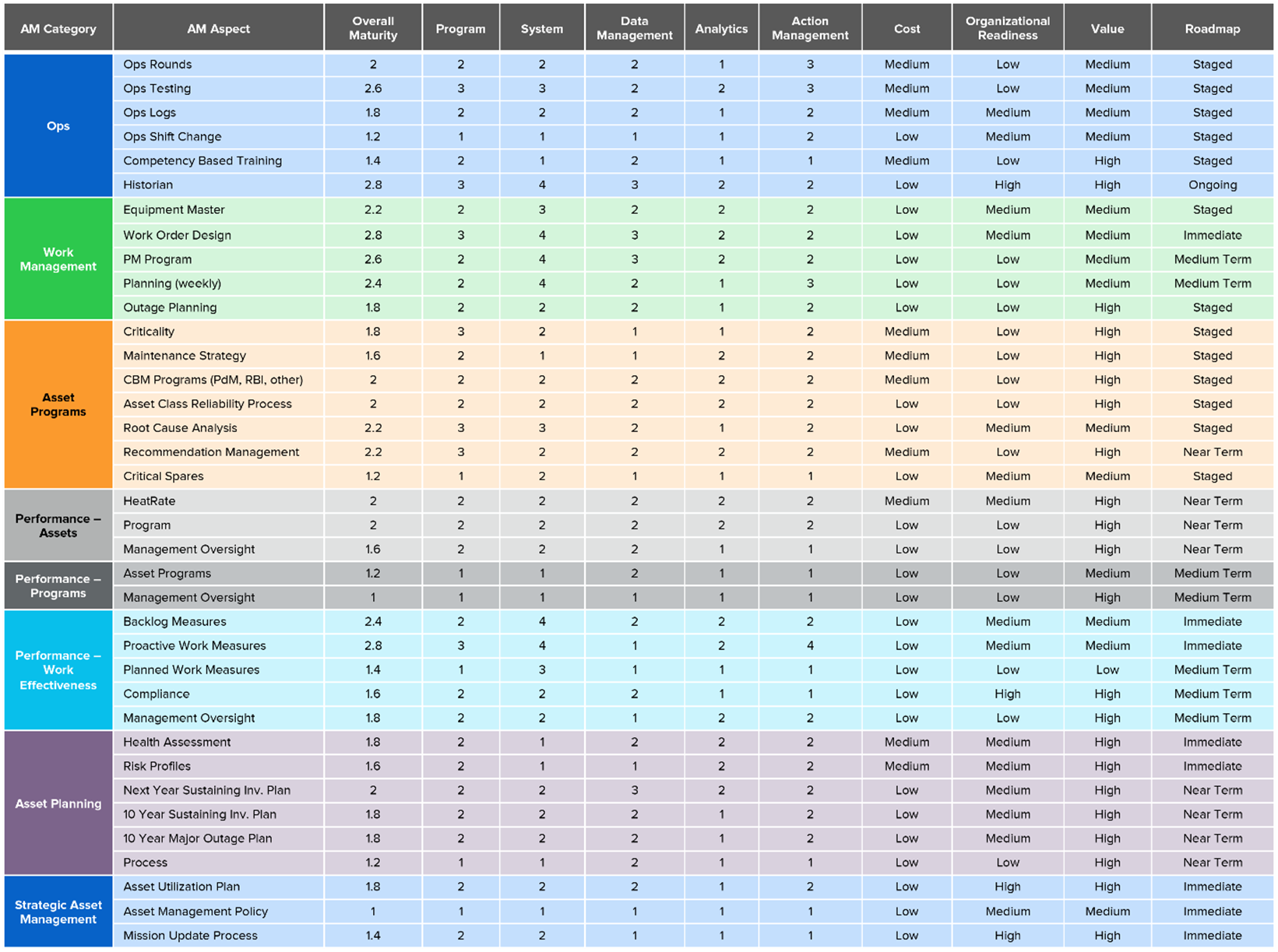

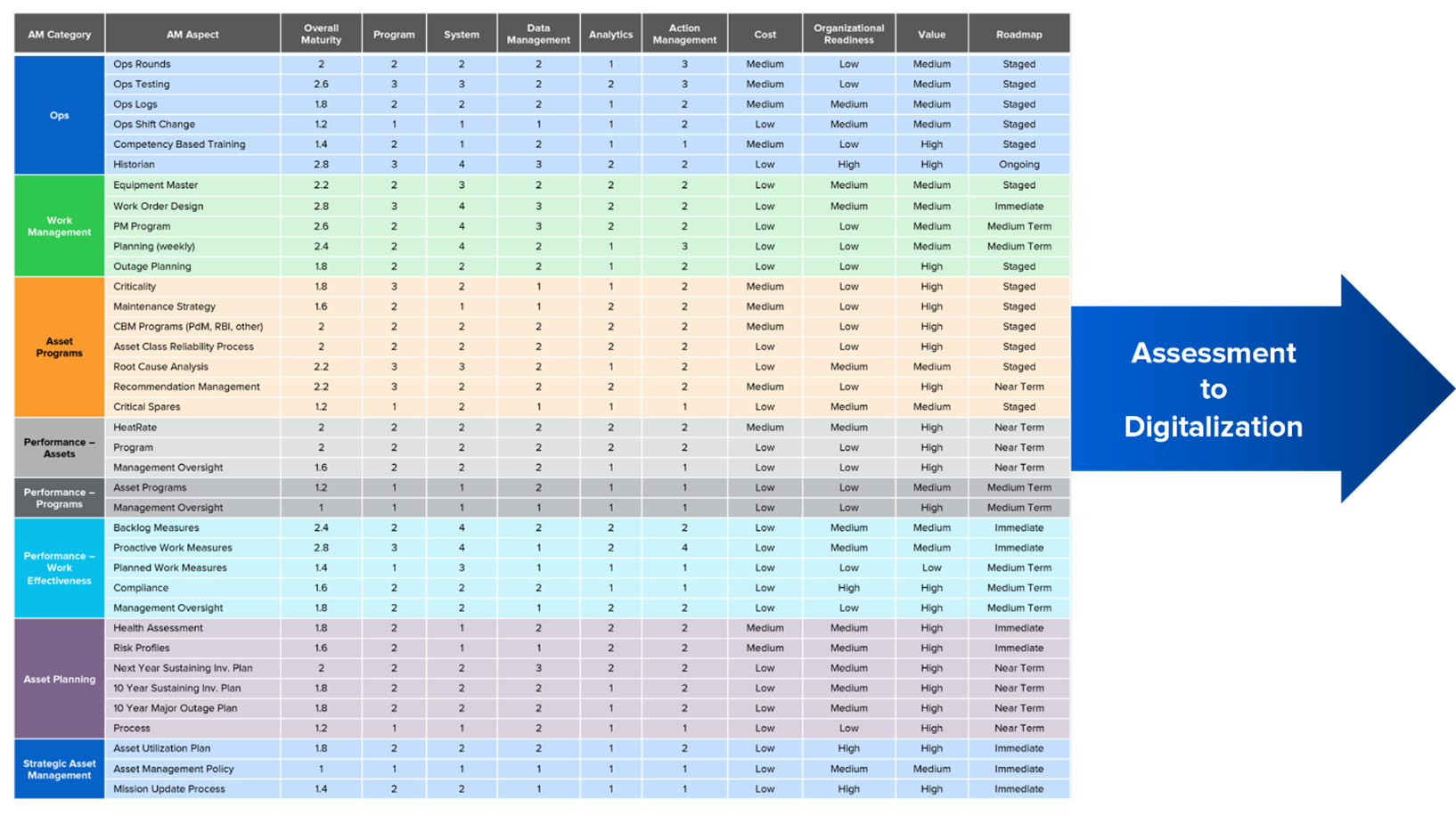

Assessing your organizational state, or competency, from an asset management ecosystem perspective, will enable you to develop the best path forward to employ digital capabilities, at the lowest cost, to meet your business needs.

The above image illustrates key assessment factors against specific aspects of the AM ecosystem. Each aspect is associated with an AM stream and layer, showing a numerical measure of strengths and weaknesses with respect to maturity, and includes change considerations, such as cost, readiness, and value.

The assessment is designed to improve your understanding of digital opportunities and to proceed via a roadmap that efficiently facilitates digitization. Furthermore, it helps you navigate the field of technology providers, as they should be required to follow your structured view of AM. It can serve to reveal their depth of capability, understanding of your needs, and provide the basis for deciding what technology to use and when.

Enhanced asset management is the pathway to "smart" digitalization. They ought not to be thought of as different things: digitization requires asset management maturity, and asset management value in turn is magnified by digitization.

-Taking a Digital Ecosystem Approach

Once an AM assessment is complete, areas of earliest digital opportunities will be apparent, and equally important, areas where more foundational development is required to take advantage of digitization will also become apparent. This will enable the optimum selection of technologies now and, enable the staging of future technological development.

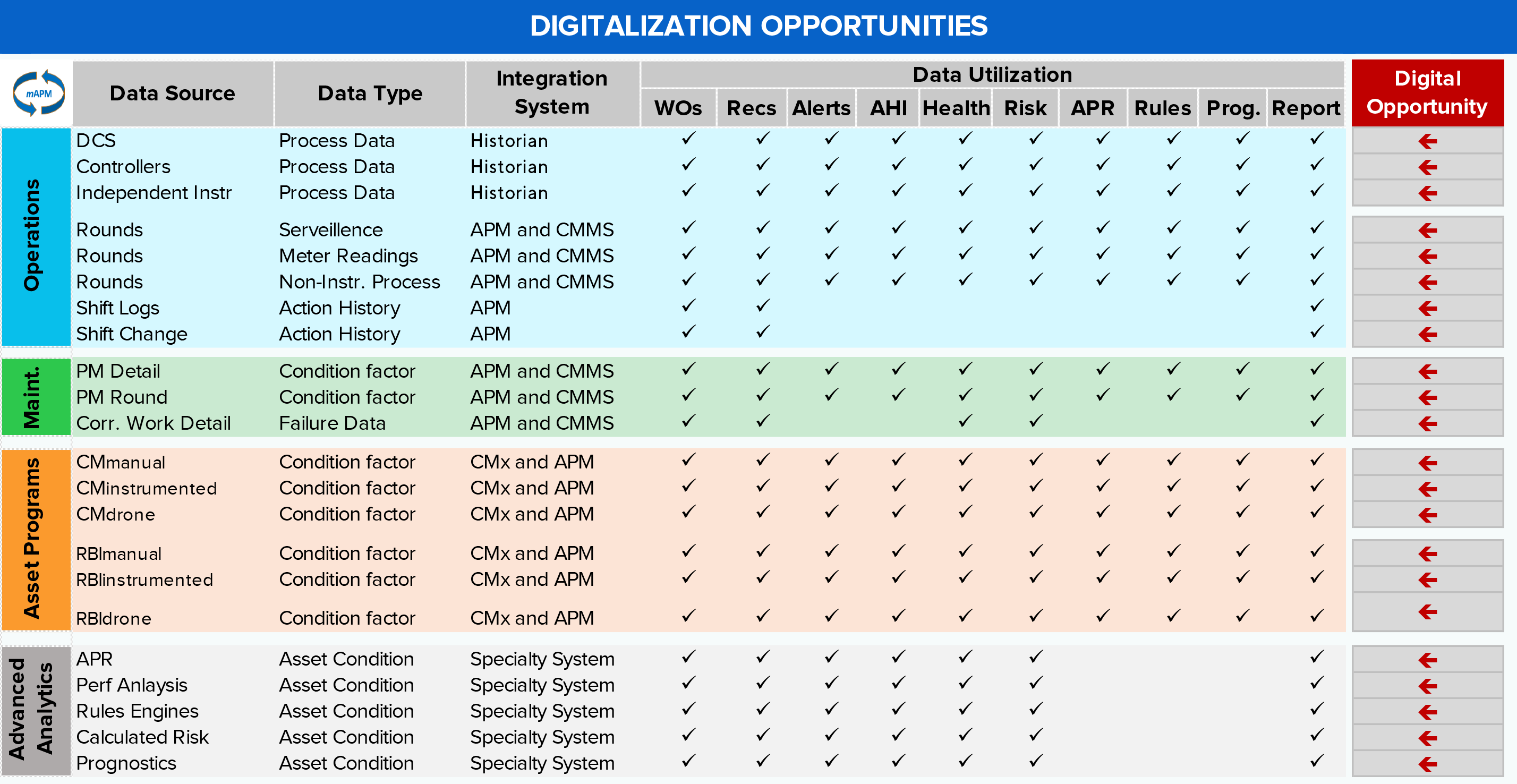

Timing of development aside, your vision should include digitally enhanced AM in specific areas as illustrated in the Digitization Opportunity Table (see below). Some of the opportunities are expanded on in the following sections related to:

- Reliability management (maintenance strategy in particular)

- Operations

- Work management

- Asset planning

- Strategic planning

- Performance management (ensuring foundational programs are working)

Reliability management

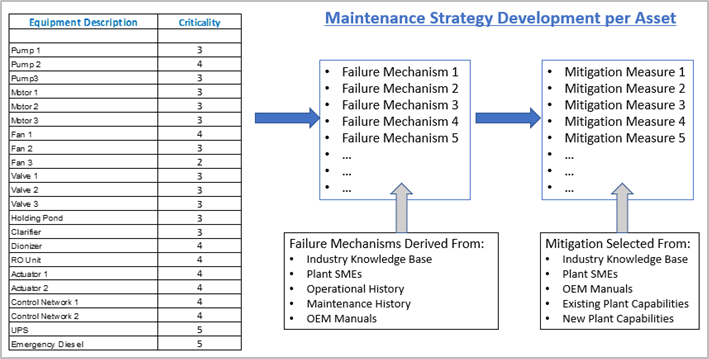

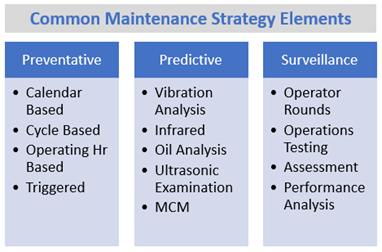

Reliability management represents the layer of AM that specifies asset care programs (preventative, predictive, surveillance activities, etc.), determines criticality, develops condition assessment criteria, and much more. It is also where new digital capabilities need to be well considered and integrated.

For example, if an organization wants to employ advanced pattern recognition (APR) or rules engines, it is important to know which assets to target. That requires an understanding of condition and process information, asset criticality, failure mechanisms, and existing infrastructure for providing data to these advanced tools. Such is the “nuts and bolts” of reliability programs and, therefore, the right place to start thinking about digital opportunities and value. In short, digitization is best considered and selected within a maintenance strategy design context.

Maintenance strategy design

Maintenance strategy is at the core of reliability management. Its influence reaches all aspects of the AM ecosystem, especially in a well-designed AM program.

For example, Maintenance Strategy:

- Determines the appropriate preventive, predictive, and surveillance activities to be conducted by maintenance, operations, and technical personnel

- Feeds requirements to work management systems, operations management systems, and condition-based maintenance management systems

- Sets criteria for, and use of, asset health data from field activities

- Drives condition-based maintenance work

- Drives risk determination and risk-based decision making

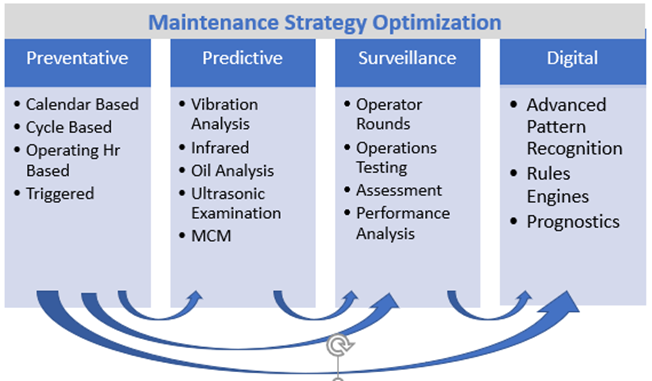

Designing and sustaining comprehensive maintenance strategy comes with significant effort and resource. Nevertheless, it is a foundational requirement to realizing value in the form of Condition- Based Maintenance (CBM) and Risk Based Decision Making. A digitally enhanced AM Ecosystem can simplify the effort and magnify the value.

Data integration and optimization

When foundational AM activities are digitized, they can be integrated with your Asset Performance Management (APM) systems to enable:

- Use of Industry knowledgebases, reducing effort

- Mobile operation rounds and testing, automatically moving results to APM system

- Preventative maintenance (PM) and condition monitoring (CM), automatically integrating results with APM system

- New sensors and edge computing devices, integrating data with APM systems

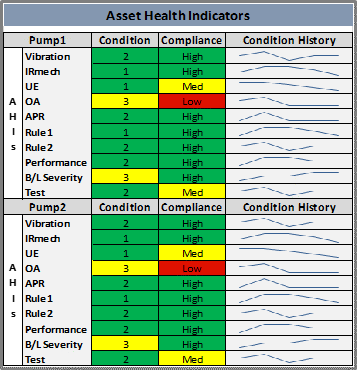

- Automated Asset Health Indicators and Calculated Risk (Health x Criticality)

And, as Asset Management capabilities continue to mature, the organization can further optimize their maintenance strategies (see Maintenance Strategy Optimization below), to replace some traditional activities with digital capabilities such as analytics and advanced digital analytics. The vision and the prize should be a maintenance strategy that delivers better asset intel, better decision making, more quickly, while reducing laborious and more costly aspects of maintenance strategy.

Challenges and considerations

Naturally, saying it is much easier than doing it. Before designing and implementing a digital plan, one needs to understand present state and readiness for change (i.e., AM Assessment). Key questions need to be answered and realities understood. In the case of Maintenance Strategy:

- Do electronic rounds exist in your business? How well are they managed? Are changes easy? Is it well used or easily used?

- Are PMs well administered and does PM data get managed? How automated is your PM data?

- What is the depth and quality of existing CM activities? Is there an overarching management system, or are there many disparate CM activities?

- Are PM, CM, sensor data, operation rounds/test data sources integrated and reside in a single accessible location? Are the associated processes well defined and managed?

Asking and answering these types of questions will enable best journey forward.

Achievable benefits

While the challenges are significant, the prize is great:

- Early detection of impending issues

- Augmentation/replacement of some traditional maintenance strategy elements

- Integration of all asset information sources to produce holistic Asset Health Indicators (AHIs), enabling more layers of digital capability

- Condition based maintenance

- Risk based decision making

Advanced analytics

Advanced analytics offer the potential for added layers of business value but require rich, accurate streams of data from field sensors (via control systems and historians), and from PM, CM, and operations programs. Findings from analytics need to be processed and translated to action.

For example, an anomaly from an advanced pattern recognition model needs the right expertise to design and assign action. And the action must get to the right person or integrate into the right work process. While comprehensive AHIs offer great potential, how they are used, assessed, integrated with other processes needs to be designed, deployed, and sustained.

Advanced analytics can be powerful and effective; however, the feeder systems must be properly working. For example, ensure that:

- PMs and CMs are conducted, and data are being produced and delivered

- The numerous CM data streams (and findings) are integrated and delivered

- Operations activities (rounds, test, logs) are well defined, and results enter the AM ecosystem

- New instruments, monitoring instruments, and edge computing are judiciously selected and deployed and are fit for purpose

- The right PM, CM, and operations activities are selected and optimized with new monitoring capabilities

Success factors

The better and more rigorous you are at maintenance strategy design, its implementation, and data integration, the better prepared you will be to take full advantage of digitization and advanced analytics.

Operations

Beyond the primary process control functions and the rich process data that Instrumentation & Control (I&C) systems provide, there are other aspects of operations related to asset management and digitization, including rounds and testing, logs, shift transfer, event intel, and work initiation.

Integrating these activities within a broad AM framework can have positive impacts on operational excellence, asset performance, and digitization value:

- Digital tools can facilitate the execution (and design) of operations activities.

- Executing these activities well can feed the AM ecosystem to enable more advanced digital capabilities.

Basic operational activities, supported by well-deployed digital tools can provide rich and structured information to the AM ecosystem to support maintenance strategy design, condition assessments, risk profiling, CBM, and risk-based decision making.

Achieving asset management excellence

In many organizations, Operations activities are still highly disparate and untapped sources of asset information or, at least, not fully utilized. Asset management and digitization can take your organization beyond good operating practice to excellence in asset management as well as operational excellence (and all that it delivers). Value streams include:

- Rounds and tests specified by maintenance strategy

- Enabled by mobile devices — automatically delivering asset condition information to APM systems, and providing compliance measurement

- Provide field data for assets with limited instrumentation — new streams of asset operating data to historians and analytical tools

- Structured operating logs that provide an accessible source of equipment history

- Enabling root cause failure analysis (RCFA) and identification of bad actors

- Providing alerts and tracking of equipment limitations across shifts

- Enabling quality shift transfers

- Ability to measure compliance and illustrate diligence

- Automated work request initiation

Each organization has different considerations. A structured assessment should illustrate your strengths, weaknesses, challenges, and value opportunity, and that should be the basis for how quickly you can effectively digitize your operations.

Work Management

Beyond the primary maintenance activities and associated competencies (critical in their own right), the work management layer of asset management plays an essential role in the success of AM and digitization:

- Enhanced CM, health assessment, predictive analytics, and risk identification enables maintainers to work on the highest priority corrective work at well-timed equipment outages or turnarounds. In other words, work on the right things, at the right time.

- Delivery of asset health information into the asset management realm relies on PM and CM activities, as well as details of work like “as found and as left” information from activities executed by maintainers.

Right work at right time

Identifying the “right work” based on health assessments, risk profiles and condition monitoring is obviously valuable and important. However, acting on the identification of highest priorities/risks is another asset management aspect that must be assessed, designed, and sustained. All the hard work and investment to deploy the latest digital tools can be wasted if the key step of integrating new systems into the work management realm is not well executed.

How recommendations from APM systems, advanced pattern recognition (APR), rules engines, etc. are generated and how they are processed in Work Management Systems and Outage Management Systems can be the difference between digital success and failure. And, rarely, is this element of AM the focus or strength of digital providers. Detailing the requirements in an AM assessment and measuring a provider’s capability in this respect is key.

Delivering asset health information

Industry relies on skilled tradespeople to sustain equipment. Digitization plays an increasing role in supporting their activities, their technical development, and their ability to deliver important asset information into the AM ecosystem. Maintainers can be supported and enabled when armed with connected digital devices:

- Receiving and updating work orders is common now

- Drawing access and augmentation/visualization tools hold the promise of increased work effectiveness

- Route information can be directly linked to asset information systems to enable collection and compliance measurement

And maintainers collect a lot of information about the equipment they are fixing. As found and as left measurements are critical to enable:

- Deeper reliability analysis

- Intel on failure mechanisms

- Optimized maintenance strategies and the resulting value

Capturing this field data is enhanced with well-designed and integrated mobile tools. Again, assessing the present state of existing capabilities and challenges will provide for the best journey toward digitization of work management.

Asset Planning

Asset planning, at a high level, represents those activities that integrate a comprehensive understanding of asset condition and risk with strategic goals and objectives, so that risk and objectives can be optimized. Asset planning should encompass:

- Short-term mitigation plans and activities (CBM, for example)

- Outage timing and scope

- Short- and long-term investment planning

- Scenario planning in support of strategic planning

This is how an organization translates asset condition and risk to asset plans. It is typically completed during the annual AM cycle.

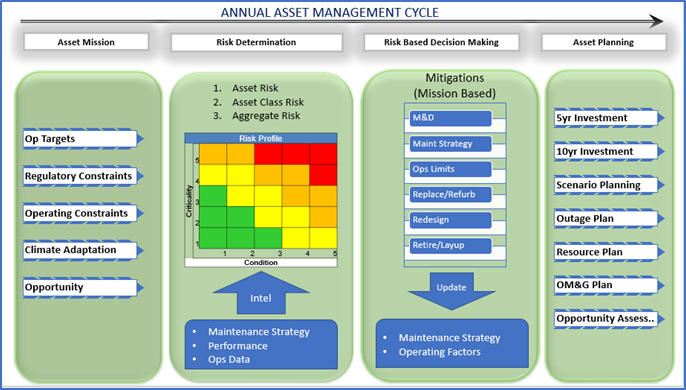

Annual asset management cycle

The annual AM cycle generally works like this (illustration below):

- Strategic mission (including asset goals and objectives) is updated annually

- Risk determination is conducted against significant assets and systems.

- Risk mitigations are determined in consideration of strategic goals.

- Asset planning ensues, which then drives into the next year’s cycle.

Asset planning is a foundational capability that is a lot less about technology than it is about process and organizational rigor. Automation (digitization) in the context of asset planning is about harnessing broad risk intel in a common system to enable decision-making and oversight. If this capability does not exist, then, the value of digitization (via condition, health, risk determination) is diminished.

- Digitization can support both asset planning and the broader AM cycle. Digital tools should be deployed to centralize risk intel and mission intel, so the annual asset management processes can be managed. But such digitization need not be complex or expensive; beware the technologies that calculate risk, (condition and criticality) with tremendous precision. Risk factors and risk determination generally involve subjectivity: Criticality factors such as safety, environmental, as well as projections of loss, are not precise ratings, which is why a 1-5 system (20% increments) is commonly utilized.

- Many asset health factors require SMEs to consume AHIs and produce a condition rating, which commonly uses a 1-5 system, as well.

- Risk is the product of criticality and condition, which means that it is not precise.

Nevertheless, this methodology produces an outcome that places most assets in sufficient risk categories to make good decisions and to focus attention on highest risk assets. Typically, it results in only a small number of risk rankings that require additional scrutiny and technical review.

Assessing the present state of asset planning is essential to determine how tools may support overall AM ecosystem design and integration of asset planning. An asset planning tool (system), however, is not the solution unto itself. Asset planning is about highly integrated organizational processes delivering risk intel to an environment that can organize, visualize, aggregate, and enable decision making. Get the processes right first, then apply a fit for purpose system.

Strategic Planning

Strategic planning relates to digitization in at least two important ways:

- It should benefit from quality asset planning.

- It should provide broad guidance for the adoption of digitization.

Benefits of digitization

As discussed, digitization can and should play a role throughout the AM ecosystem to enable best understanding of risk. Armed with a strong understanding of asset risk, organizations can project risk into the future and calculate scenarios that estimate OPEX and CAPEX, along with asset life and performance expectations; thereby, supporting strategic decision making.

Strategic guidance on digitization adoption

Many organizations believe that digitization, automation, and all associated technology, will be a crucial factor in future success. So, it is important to set a digital course for the business. Where many businesses fail, however, is that they frame, and believe, that digitization is the goal. As a result, it takes on a life of its own, as opposed to playing a primary role in supporting AM objectives. This can lead to disconnected projects and disappointing digitization results.

Mature organizations seek a structured approach to assessing, with depth, the value of digitization, the challenges (human, process), and the cost. They search for the digitization approach that works for their specific business, while also meeting their strategic goals.

Performance Management

There are requirements for successful digitization, and successful asset management:

• Maintenance strategy must be well designed and deployed.

• Resultant data must be well defined and managed.

• Data must be integrated and synthesized to provide accessible asset health information.

• Intel generated to drive condition-based maintenance (CBM) and risk-based decision making (outages, refurbs, investment).

• New streams of data must also be integrated to enable emerging analytics.

Ultimately however, success will be measured by key performance indicators (KPIs) such as:

- Asset Performance: reliability, availability, other asset failure measures, efficiency, etc.

- People Performance: work effectiveness, productivity, safety, etc.

These are critical lagging measures that should be positively impacted by digitization. But there are other, important “leading measures” to consider, such as:

- Program Performance: programs (such as criticality assessment, maintenance strategy, root cause analysis, operational technology, condition assessment, risk profiling, recommendation management, etc.) must be measured and managed, with respect to:

- Design & deployment

- Compliance

- Data capture

- Data integration and synthesis

Successful digitization will require this clarity to develop and sustain a more sophisticated asset management environment. Therefore, assessing performance management capability (and addressing the gaps) is critical to enable the best asset management and digitization journey.

Review and management oversight

Finally, with all the process and data design, integration, analytics, dashboards, and scorecards in place, one final and decidedly non-technical effort remains. Regular review and appropriate management oversight are essential to translate performance measurement to performance management. This review process must be a top organizational priority and, armed with quality information, enables the best possible management oversight and decision making.

From a management perspective, there is a vital role for digitization within the performance oversight program, itself. Gathering data from various systems to create clear visualization of performance (dashboards and scorecards) in a way that is consumable at each level of management is vital. Managers and senior management rely on these consolidated views of performance (measures, KPIs, trends, analytics) to understand performance, make management decisions, and provide coaching and support where it is most needed.

The Moral of the Digitization Story

Thinking about digitization in the context of asset management and your AM ecosystem will enable you to build the road map that enables your organization to “digitize with a purpose” and, get better at asset management as well.

Here are the key takeaways:

- Each organization is unique.

- Each organization should have its own optimal “digital road map.”

- Understand your starting point, and then plot your digitization journey.

- A methodical assessment of your AM ecosystem brings clarity to the foundational competencies required to employ digitization.

- Assessment enables you to select and stage technologies with consideration for your people, strategic goals, strengths, weaknesses, and business value.

- There are some undeniable and consistent requirements (foundational asset management competencies) to succeed at digitization. These competencies will add value regardless of the level of digitization.

- Demand that your providers meet your AM digitization goals.

About the Author

Rob MacNeil

Rob is currently President and Principal at MacNeil Asset Performance Management. He is a Professional Engineer with over 30 years of experience in the utility industry including operations, maintenance, planning, engineering, and management. In those roles as well as his current role, Rob has led the design, deployment, and operation of highly successful Asset Management Programs and Asset Performance Management Systems.

Rob has a Bachelor of Science in Physics from Dalhousie University as well as a Bachelor of Engineering in Electrical Engineering from the Technical University of Nova Scotia.

Connect with Rob on LinkedIn.

ABOUT ALLIED RELIABILITY

Allied Reliability provides asset management consulting and predictive maintenance solutions across the lifecycle of your production assets to deliver required throughput at lowest operating cost while managing asset risk. We do this by partnering with our clients, applying our proven asset management methodology, and leveraging decades of practitioner experience across more verticals than any other provider. Our asset management solutions include Consulting & Training, Condition-based Maintenance, Industrial Staffing, Electrical Services, and Machine Reliability.

Subscribe to our Blog

Receive the latest insights on reliability, maintenance, and asset management best practices.