Work Sampling: Why Is It Needed?

What Is Wrench Time?

Wrench Time is defined as the actual amount of time a craftsperson spends doing value-added work. A Wrench Time Study, or Work Sampling Study, is aimed at identifying and then eliminating or mitigating the time spent on non-value-added tasks.

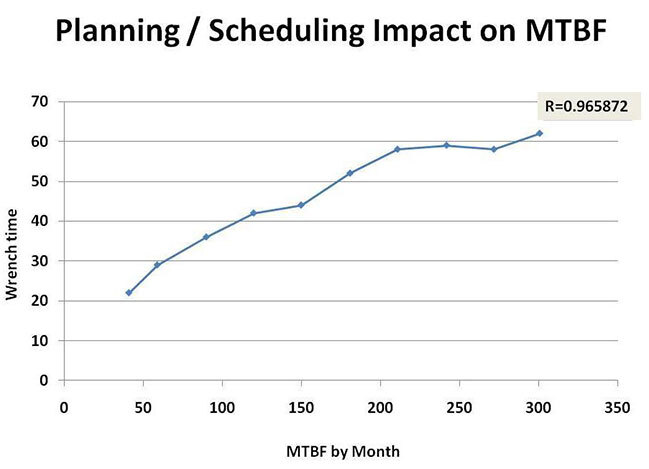

World Class Wrench Time is 55-65%; Wrench Time for most companies is between 18-30%.

“Your system is perfectly designed to deliver precisely the results you’re getting.”

–W. Edwards Deming, PhD

Guiding Principles of Wrench Time Studies

Identify the percent of time maintenance personnel are delayed due to one of these specific reasons:

- Traveling to and from the workplace: items not in the plan

- Breakdown Planning: (emergencies or urgent work) waiting for parts, people, etc.

- Training: technical, safety, etc.

- Meetings: training, safety, etc.

- Work Execution: waiting on parts, waiting on someone, etc.

- Breaks: lunch, heat breaks, etc.

- Waiting: waiting on a supervisor, another maintenance person, production, etc.

- Administrative: Union issues; personnel issues; discussion with a supervisor about vacation, work orders, etc.

“Drive out fear, so that everyone may work effectively for the company.”

–W. Edwards Deming, PhD

Warning

We never want our employees to fear any actions we take as managers. If a wrench time study is to be conducted, it is necessary to discuss the reasons for the study and its value.

Do not follow the “just do it” approach. You want your maintenance personnel to buy into the process.

The only reason for conducting a Wrench Time Study is to identify the delays causing maintenance to be less efficient.

Pay Attention to This Message:

A Wrench Time Study is not about finding personnel who are inefficient, making mistakes, or performing poorly. It is about the quality of the planning process and how the organization uses the planning process.

How Is a Work Sampling Study Conducted?

Over the years, Work Sampling Studies have taken many forms. The most infamous is the Industrial Engineer following someone around all day with a clipboard and stopwatch. This technique rarely achieves accurate results.

Our company prefers a different method. The Assessor puts his eyes on every craft once or twice every hour, placing a tick mark in the category of what they are doing at that instant. It is good if tick marks can be put in the Direct or Indirect categories. That is, they are contributing to work completion. All other categories populate the Non-contributory category.

Learn how our Reliability Consulting Services can help your company develop and implement an efficient equipment maintenance plan.

ABOUT ALLIED RELIABILITY

Allied Reliability provides asset management consulting and predictive maintenance solutions across the lifecycle of your production assets to deliver required throughput at lowest operating cost while managing asset risk. We do this by partnering with our clients, applying our proven asset management methodology, and leveraging decades of practitioner experience across more verticals than any other provider. Our asset management solutions include Consulting & Training, Condition-based Maintenance, Industrial Staffing, Electrical Services, and Machine Reliability.

Subscribe to our Blog

Receive the latest insights on reliability, maintenance, and asset management best practices.