Equipment maintenance plans (EMPs) identify all the specific equipment failure modes and the corresponding tasks needed to mitigate the risk of each failure mode. By executing these tasks, optimal equipment performance is maintained, and any performance degradation can be identified long before a full functional failure.

Connect Insight to Execution

Equipment Maintenance Plan

Reduce intrusive maintenance actions while increasing equipment availability.

A maintenance plan identifies the specific tasks necessary to minimize failure mode consequences. It also contains information that guides work order scheduling, informs spare parts management, and provides pertinent information for budgeting maintenance resources and communicating downtime requirements to operations. The elements of the maintenance plan can be broken down into three categories of information: asset, task, and support.

Asset Elements

- Equipment Name or Type - The name or type of equipment to which the EMP applies.

- Equipment Criticality Ranking - The ranking or rating given to the equipment based on the results of your criticality analysis.

- Manufacturer and Model - Include all the equipment models to which the EMP applies.

- Component - The nomenclature used within your CMMS to identify the specific asset for which the maintenance task applies.

- Function and Functional Failure - List the performance expectations, or functions, of the component and the ways in which the component fails to meet the required function.

- Failure Mode - The reasons why the component fails to meet expectations, and the basis for prescribing the maintenance task within the EMP.

- Failure Mode Criticality – This is the significance of the failure mode based on the results of your failure mode, effects, and criticality analysis (FMECA) or prioritization matrix.

Task Elements

- Maintenance Requirement Number - A unique alphanumeric identifier that distinguishes each task within the EMP.

- Task Type - Describes the actual maintenance activity that will be performed on the equipment.

- Task Description - The purpose of the task.

Support Elements

- Equipment Condition - The mode of operation required when performing a maintenance requirement task.

- Craft - The skill level of the individual performing the task or, at a minimum, the craft type.

- Crafts Required - The estimated number of maintenance resources required to complete the task.

- Frequency - The periodicity of the maintenance requirement, such as weekly, monthly, quarterly, etc.

- Duration - The estimated amount of labor hours needed to perform the maintenance requirements.

- Materials and Tools - The materials and special tools associated with each task on the EMP.

How Allied Reliability Can Help

As part of the equipment maintenance plan (EMP) development process, Allied Reliability consultants will work with your maintenance teams to create a preventive maintenance (PM) and predictive maintenance (PdM) plan.

To accelerate the creation of the EMP, Allied Reliability bases its development on failure mode analysis (FMA). During the process, Allied will focus on the predominant failure modes in your facility that have occurred and are likely to reoccur. Focusing on the most common or critical failure modes helps to separate value added tasks from non-value-added tasks. This approach can be applied to the creation of an EMP or the redesign of an existing EMP.

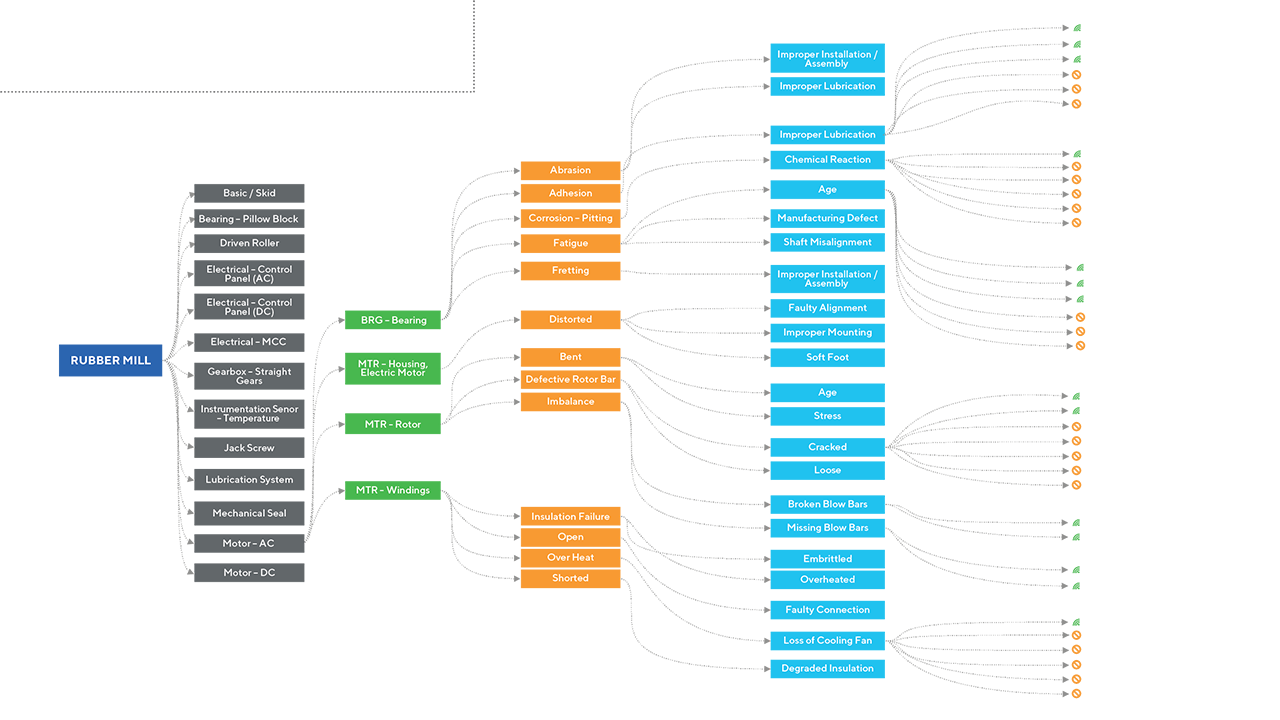

Allied leverages its own failure mode library to identify the equipment and component level failure modes correctly. Allied’s tool contains thousands of asset failure modes that have been cataloged down to the component and part level. Additionally, using over 20 years of equipment failure history, we have already mapped the recommended tasks to mitigate each failure mode and the proper frequency to perform that task.

An example is provided below.

As a part of our effort to create a failure mode-driven maintenance strategy, we must decide how much of our equipment will receive a full reliability-centered maintenance (RCM) Analysis. Through years of experience, Allied Reliability has found that a full-blown RCM Analysis need only be performed on 5-20% of all the machines in a facility to address most of the equipment failures creating unplanned downtime. Asset criticality ranking will be used to determine the 5-20% of critical assets.

NOTE: This does not preclude an RCM Analysis from being performed on any machine at any time. After a maintenance strategy is put into place, RCM Analysis is a very powerful tool to use on any machine, regardless of critical equipment ranking, that exhibits chronic failures (otherwise known as a bad actor).

From there, our consultants will utilize customer equipment data and our failure mode library to identify component failure modes, functional effects, and the risks associated with a failure to determine the proper task to mitigate each failure mode. An equipment maintenance plan document will be created for each piece of equipment containing pertinent information including name, asset type, designed failure modes, and the associated tasks recommended to mitigate each failure mode.

The task data will be specified by:

- Predictive / Preventive maintenance (PdM/PM)

- Periodic time-based frequency

- Task owner

- Time for completion

- Mode of operation (running or stopped)

- Corrective action, if applicable

- Action owner

- Mode of operation while applying corrective action

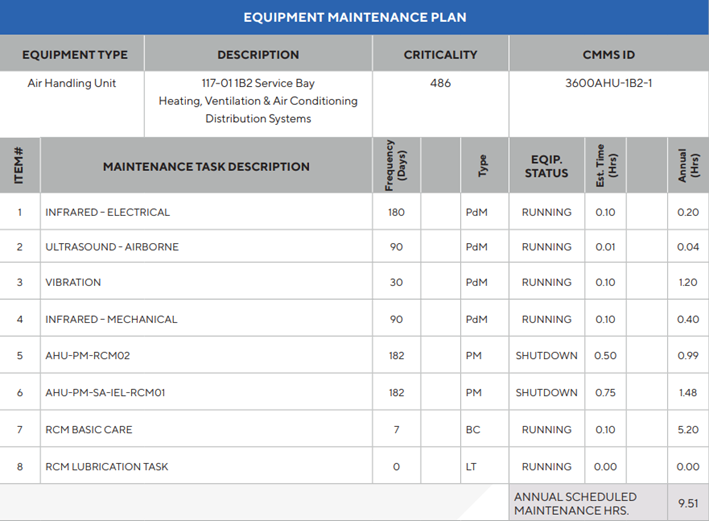

Sample Equipment Maintenance Plan for an Asset. This data can be provided in excel file format enabling the customer to upload the resulting equipment maintenance plans or any portion desired into their preventive maintenance software such as a computerized maintenance management system (CMMS) or enterprise asset management (EAM) system for direct use in their maintenance schedules and work orders.

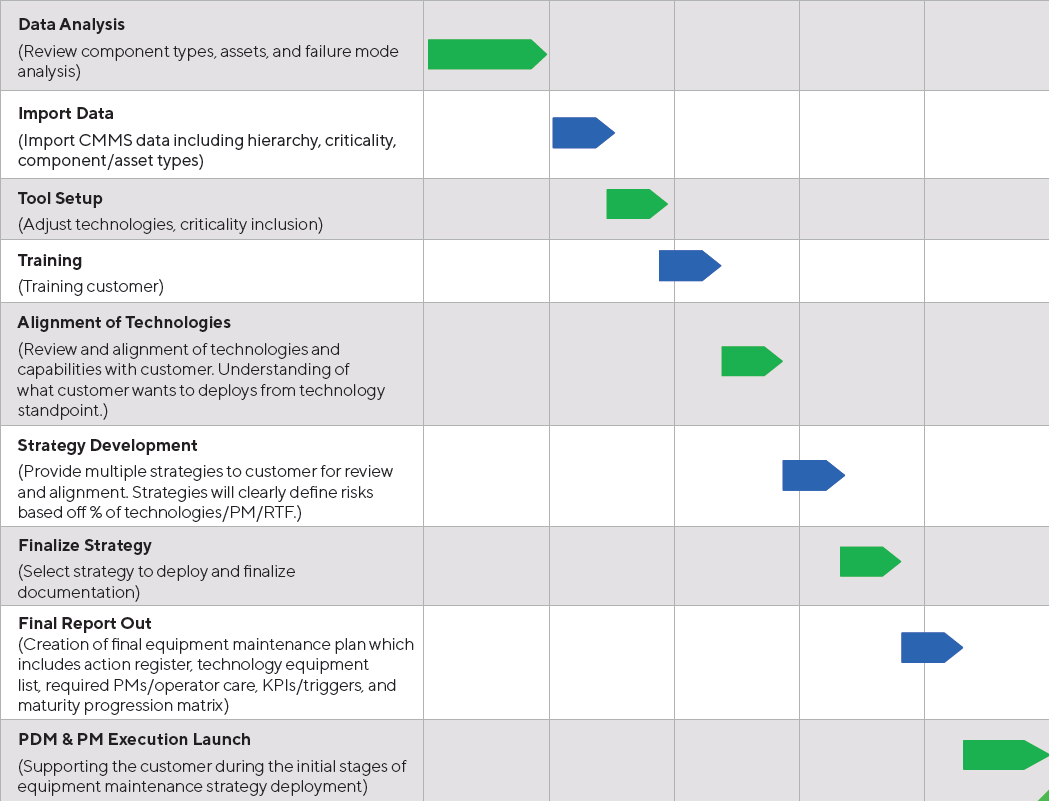

A typical EMP engagement follows a guideline like the one outlined below:

Once the EMP is developed and implemented, the organization should strive to continuously improve. When the failures that have occurred do not match the expected failures, methodologies like root cause analysis (RCA) provide an opportunity to analyze these situations and devise an adjustment to the current approach.

An important part of the EMP is the preventive maintenance plan.

A preventive maintenance plan is a systematic approach to maintenance in which equipment, machinery, or systems are regularly inspected, serviced, and repaired to prevent breakdowns, failures, or other issues. Preventive maintenance is proactive, which is the opposite of reactive maintenance which responds to equipment failure after it occurs. The goal of preventive maintenance is to save time and money in the long run.

Key components of a PM program include:

- Scheduled Inspections: Regular inspections of equipment to identify any signs of wear, damage, or potential issues.

- Routine Servicing: Performing routine maintenance tasks such as lubrication, cleaning, tightening of parts, and replacing worn components according to a preventive maintenance schedule.

- Predictive Maintenance: Using data and analytics to predict when maintenance is required based on factors such as equipment condition, usage patterns, and historical performance data.

- Record-keeping: Maintaining detailed records of maintenance activities, including inspection reports, service logs, and repair histories, to track each asset's maintenance history.

- Training and Education: Providing training and resources to maintenance personnel to ensure they have the skills and knowledge to carry out preventive maintenance tasks effectively.

- Priority Setting: Prioritizing maintenance tasks based on factors such as equipment criticality, safety considerations, and potential impact on production or operations.

- Continuous Improvement: Regularly reviewing and refining the preventive maintenance program based on feedback, performance data, and emerging best practices to optimize its effectiveness over time.

Organizations that implement a preventive maintenance program minimize unexpected equipment downtime, reduce maintenance costs, improve safety, and maximize the reliability and efficiency of their equipment and facilities. Preventive maintenance programs can include anything from scheduled visits by a maintenance technician to deep cleaning of facilities. Other advantages of preventive maintenance include:

- Extended Equipment Lifespan: Regular maintenance and servicing can help prolong the lifespan of equipment and machinery, reducing the need for premature replacements and lowering overall capital expenditures.

- Improved Reliability: Well-maintained equipment is more reliable and less likely to experience unexpected breakdowns, which increases productivity and efficiency.

- Enhanced Safety: Regular inspections and maintenance help ensure that equipment is functioning properly and meets safety standards, reducing the risk of accidents and injuries in the workplace.

- Optimized Performance: By keeping equipment in optimal condition, preventive maintenance helps maintain consistent performance levels, ensuring that production targets are met and quality standards are maintained.

- Decreased Energy Consumption: Equipment that is regularly maintained uses less energy and releases fewer greenhouse gases than equipment that is not part of a preventive maintenance strategy.

Preventive Maintenance Examples

The tasks included in a preventive maintenance plan depend on the equipment. A preventive maintenance checklist for batteries might include checking battery levels, cleaning terminals, and performing capacity tests to ensure reliable backup power in uninterruptible power supply (UPS) systems, emergency lighting, and other critical equipment. A preventive maintenance checklist for electrical systems could include testing electrical components, connections, and wiring.