Allied Reliability uses a Targeted Reliability-Centered Maintenance approach, which is a fully compliant SAE JA1011-12 Reliability-Centered Maintenance (RCM) analysis methodology that incorporates one or two facilitators who focus on small portions of the plant to accomplish rapid, cost-effective results.

Reliability-Centered Maintenance Services

What is the Overall Goal of a Reliability-Centered Maintenance Program?

The overall goal of reliability-centered maintenance is to achieve inherent reliability in any system. Through the Targeted RCM approach, Allied Reliability uses a team-based approach designed to answer the seven basic RCM questions to produce a maintenance strategy to achieve that goal.

- What are the asset's functions and associated performance standards in the present operating context? (Function)

- In what ways does it fail to fulfill its functions? (Functional Failure)

- What causes each functional failure? (Failure Mode)

- What happens when each failure occurs? (Failure Effects)

- Why does the failure matter? (Failure Consequences)

- What can be done to predict or prevent each failure? (Task Selection)

- What should be done if a suitable preventive task cannot be found? (Redesign/No Scheduled Maintenance)

The output of the Targeted RCM program is a complete maintenance strategy, from condition monitoring tasks to plans to surround the Run‐to‐Failure (RTF) components. The Targeted RCM process is very effectively used to analyze systemic problems and operating envelope problems that manifest as component-level defects.

The 5 Major Steps of a Targeted RCM Program

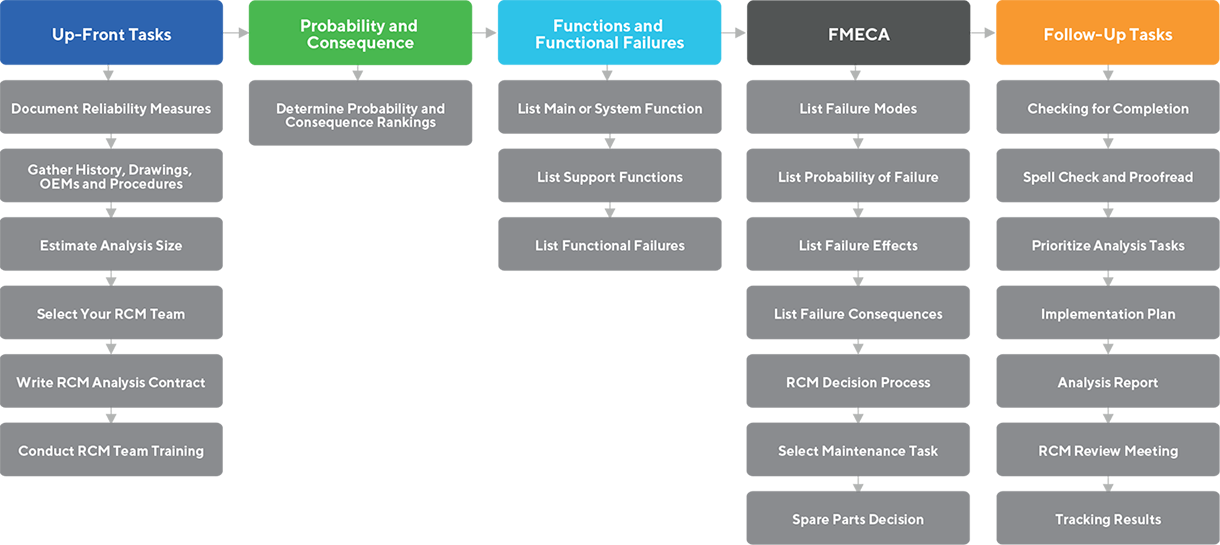

- Up‐Front Tasks – Set up the RCM facilitators and the team for success.

- Probability and Consequence – This is where we will build the groundwork for understanding the importance of each individual failure mode and developing sound methods to prioritize RCM tasks.

- Functions and Functional Failures – The roadmap to successful implementation of RCM analysis. World-class companies understand the importance of addressing maintenance tasks at the functional failure level.

- FMECA – The heart and soul of RCM. The work is done here: identifying failure modes, describing failure effects, and developing maintenance tactics. The correct tactic might be condition-based maintenance, preventive maintenance, or a system redesign if necessary.

- Follow‐Up Tasks – Designed to help the team quickly move forward and drive the implementation of the RCM tasks. Follow‐up is just as important as the analysis itself, and like everything else, it has a process that must be followed.

These five major process steps and their associated steps are shown in Figure 1.

Selecting Assets for RCM Analysis

To make RCM become a part of company culture, we need to select winners – critical assets that are suffering from equipment‐related quality, speed, and operational losses. A criticality analysis must be performed or accessible to help select assets that will provide the best return for the RCM effort.

The key to making RCM a part of the company culture is to provide an ROI for performing and implementing the RCM analysis. This is very easy to accomplish by performing Targeted RCM on the very top, critical assets.

Making Sound RCM Decisions

As we performed Targeted RCM analyses of several assets at our clients’ facilities, it became clear why some were not having the success they had expected from their Predictive Maintenance (PdM) program. In working with their PdM service provider to set up their PdM program, they simply generated a list of assets for each specific technology. The list generated for critical assets set up PdM routes and intervals for each asset based on the provider’s recommendations.

In most cases, vibration analysis and airborne ultrasonic tasks were performed monthly, thermographic inspections were set up every quarter, and motor current analysis was performed every six months. Not one single PdM inspection detailed the events that caused each failure that the tasks were looking to detect. While they all understood the P‐F curve and the P‐F interval, they failed to understand or determine why the assets were failing over and over again.

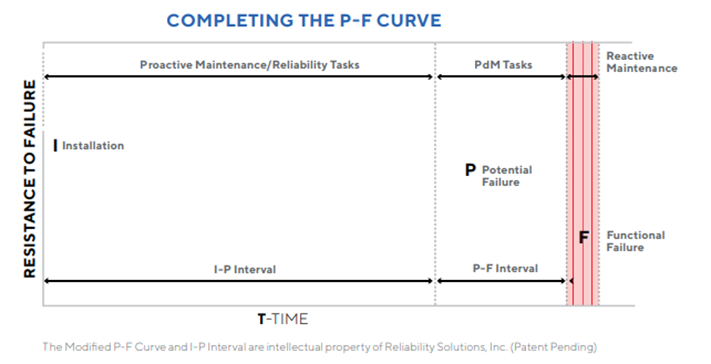

While the technologies our client had invested in successfully detected failures, our client had never asked the service provider why some assets continued to fail repeatedly. This is where the addition to the P‐F curve comes in. Note the difference in the P‐F curve shown in Figure 2. Starting at the far left (point I ‐ Installation) and moving right, we have a very long flat line going between point I and point P (Potential Failure).

This is the I‐P interval, which represents the time it takes to move from the point of Installation to the point where Potential Failure is first detected. The objective of all world-class maintenance and reliability organizations should be to maximize the I‐P interval. This can only be achieved through thoroughly understanding your assets, proactive maintenance techniques, and reliability tools. It became clear to our client that a large percentage of the failure modes they were detecting with predictive technologies could in fact be identified and eliminated using RCM and proactive maintenance techniques.

As an example, one of the failures our client saw over and over again was on a blower that was mounted to an undersized foundation. Each time they replaced the blower, they used precision alignment to ensure the blower and motor sheaves were properly aligned. Without proper foundational support, the continued stopping and starting of the blower over time resulted in misalignment and degradation of the blower and motor bearings.

In performing the Targeted RCM analysis of this asset, we listed all the probable failure modes for the blower and determined that the blower base and foundation would need a redesign to eliminate the failure mode. The result: a blower that had failed three times in eighteen months has not failed in over four years.

In completing the P‐F curve, we have identified several proactive maintenance techniques and reliability tools that can be used to extend the I‐P interval. These tools and techniques are described below.

Understanding Proactive Maintenance Techniques and Reliability Tools

While it would take a full textbook to completely explain the value of each proactive maintenance technique and reliability tool, each is listed here with a summary of how they can extend the I‐P interval.

Reliability-Centered Maintenance

As discussed, RCM is a reliability tool that uses a structured team approach to analyze a process or piece of equipment. In performing an RCM analysis, your team will assess all likely failure modes for the asset and develop a maintenance strategy to mitigate the consequences for each failure mode. The value in performing RCM is the proactive assessment of these failure modes and the resulting tasks developed to eliminate reoccurring failures.

Failure Modes and Effects Analysis (FMEA)

Like RCM, FMEA is a reliability tool used in the design phase to identify likely failure modes. In performing FMEA your design team will discuss these failure modes and attempt to design out failure modes that result from poor design and installation decisions.

The Five Rights of Reliability

Design it right, purchase it right, build it right, operate it right, and maintain it right. This produces an overall reliability program focused on educating employees at all levels and organizations on the importance of reliability. The five rights of reliability develop a reliability plan across engineering, purchasing, construction, operations, and maintenance that clearly describes how each business unit can improve reliability.

Select Supplier Agreements

Often a part of your reliability plan, select supplier agreements should be made consulting engineering, operations, maintenance, and purchasing. These agreements should be developed using the company’s reliability data while working with suppliers to provide the most robust and reliable assets. Inferior parts or components are a common cause of reoccurring failures.

Requirements Documents

If this is not part of a company’s capital design and engineering program, it needs to be. Requirements documents are binding agreements written to ensure the highest level of reliability in design and installation. For example, many companies now have requirements documents written for the acceptable vibration level on start‐up of new rotating equipment. The document will clearly state what that acceptable measure will be, and the resulting action taken if the requirement is not achieved. Again, the intent of these documents is to eliminate failure modes inherent to poor design or installation practices.

Design Standards

Company design standards should always be used as a tool to improve equipment reliability and prevent equipment failure. Used in combination with select suppliers and requirements documents, design standards will help your company ensure all new installations are safe and reliable. Some examples of design standards that will eliminate reoccurring failure modes include standard mass requirements for pump foundations, standards requirements for piping supports, and standards for starter panel installations.

Precision Alignment and Balancing

Precision maintenance tools are known for increasing the life of rotating equipment. While these tools have been available for several years, few of us have taken advantage of their use. Precision alignment and balancing will both dramatically reduce vibration that results in reoccurring failures of bearings, seals, and couplings.

Installation Standards

Used for both new installation and maintenance, these standards are put in place to ensure proper craft skills are used when working on equipment/assets. Some examples of installation standards would be the identification of the proper type and grade of flange hardware and gasket material. Developing installation standards eliminates reoccurring failures such as leaks caused by using incorrect gasket material.

Torque Specifications

While almost everyone working in maintenance knows what a torque wrench is and what torque specifications are, they are seldom used. Leaking connections, loose rotating equipment, and sight glass failure are often the result of improper torque. While using a torque wrench and following the specifications may take more time, the resulting reliability will increase the I‐P interval.

Precision Tools

To ensure proper maintenance and installation practices, personnel need precision tools to do the work. It is easy to quickly assess the level of understanding concerning reliability with a quick look in the toolboxes of the company’s maintenance people. Hammers, channel‐locks, pry bars, and screwdrivers alone will begin to ensure reliability. Precision work requires precision tools, and if the maintenance personnel do not have these tools, do not expect results to improve.