On-Demand Webinar

Be sure to check out our webinar, “The Real Cost of a Poor Asset Hierarchy”

You may ask, “Why should I take the time and trouble to put my equipment and assets into a logical hierarchical order?” We believe it is well worth the effort to create an equipment hierarchy structure that allows for the following:

Creating an asset hierarchy also involves creating a standardized set of naming conventions (taxonomy) for labeling your equipment and assets. Finally, housing all this data in a Computerized Maintenance Management System (CMMS) allows for centralized tracking and reporting.

A good asset hierarchy:

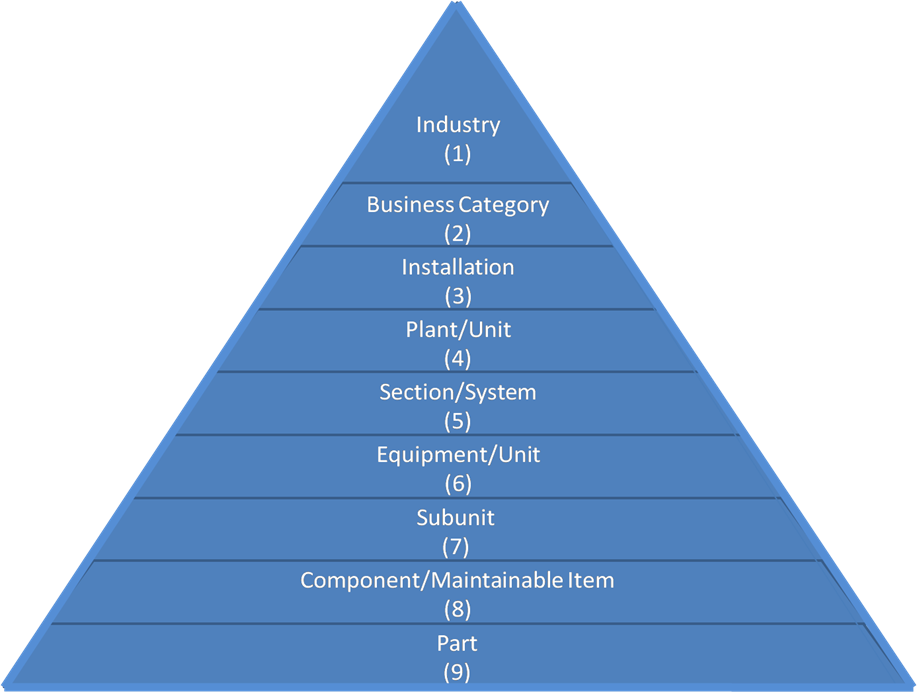

The oil and gas industry has developed an equipment hierarchy pattern documented in the ISO 14224 standard. This is a recommended method for organizing assets logically and consistently.

Different industries or companies will have different needs; therefore, hierarchies and naming conventions should be customized to reflect your facility operations best. The critical thing to remember is that any item that may be worked on should be captured in the CMMS; otherwise, how can you report on its condition and conduct effective maintenance?

There are several ways to organize your hierarchy data effectively. The different methods of organizing the hierarchy include:

You can get started by evaluating your current asset hierarchy in your enterprise asset management (EAM) system in accordance with the ISO 14224 standard shown above. The master equipment list should include taxonomies assigned to the equipment and specification data, including manufacturer, model number, and serial number, as determined by vendor documents or nameplate data.

Using a CMMS, you can set up consistent naming of equipment and assets so they are easy to find and view related data at a glance. This can be a simple exercise, keeping the following best practices in mind:

The automated capabilities of a CMMS provide a way to gather asset data for driving equipment reliability and process improvement. Without reliable asset data, it is difficult, if not impossible, to effectively allocate already scarce maintenance resources. Poor asset data leads to making decisions based on whatever is causing the most pain today.

Having a complete equipment hierarchy defined isn’t enough, and it is a waste of time if you don’t use it. Once the hierarchy is complete, an effort to prioritize the equipment should be performed. Root Cause Analysis (RCA) and Failure Mode and Effects Analysis (FMEA) can be helpful tools to assist with your prioritization efforts.

This will allow you to prioritize the work execution efforts to organize and prioritize the efforts of the maintenance department more efficiently and effectively. It also helps set priorities for preventative and predictive maintenance activities, allowing for early identification of problems and their resolution BEFORE a production stoppage occurs. Ultimately, this helps create a safer workplace with fewer HSE incidents.

Having a well-organized hierarchy can significantly enhance your reliability efforts. It is the foundation of any successful maintenance and reliability program. A comprehensive equipment hierarchy is the backbone of any CMMS (otherwise known as an asset management system). It’s an essential step towards achieving condition-based maintenance tasks and a more reliable operating environment to be more competitive in the marketplace.

Be sure to check out our webinar, “The Real Cost of a Poor Asset Hierarchy”

Allied Reliability provides asset management consulting and predictive maintenance solutions across the lifecycle of your production assets to deliver required throughput at lowest operating cost while managing asset risk. We do this by partnering with our clients, applying our proven asset management methodology, and leveraging decades of practitioner experience across more verticals than any other provider. Our asset management solutions include Consulting & Training, Condition-based Maintenance, Industrial Staffing, Electrical Services, and Machine Reliability.

Receive the latest insights on reliability, maintenance, and asset management best practices.